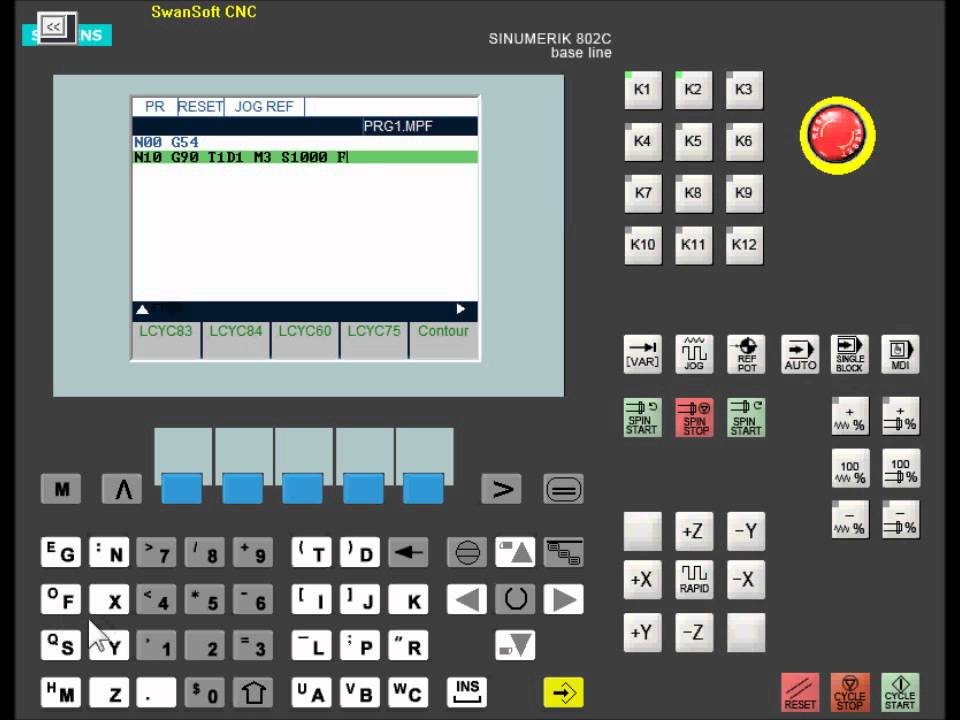

Sinumerik Cnc Macro Programming Manual

Siemens sinumeric system(CNC controller) operating and programming guide for 802d,802dsl,840d,810d systems by 840dsl in Types > Instruction manuals and suyog kulkarni. Functions Using SAS MACRO and SCL.

R Parameter programming and Programming Jump instruction is an advanced programming method in SIEMENS system and similar to the macro program in FANUC system. It uses parameter variables instead of functional codes and address values to make up a processing program. The R variables can plus, minus, multiply, divide, evolution, power, trigonometricfunction and so on in the logical calculation, In NC machining programming, uses R Parameter programming and is Programming Jump instruction, may realize the NC procedure logical judgment, comparison, transfer and other logic operation, resulting in a greatly simplified program, provides some solutions to numerical control programming for some special, complex and the similar parts. Abstract: Bonnet tool polishing, combined traditional optical polishing technique with modern NC technology, is an novel optical polishing technique.

As the motion control and material removal process is different from metal cutting NC machine tool, the NC programming for bonnet tool polishing NC machine tools cannot be carried out with commercial CAM software. This paper analyses the kinematics of feed mechanism and precession mechanism using coordinate transformation method and sets up the feed and precession kinematics equations. The arithmetic of post processing applied to NC automatic programming system is proposed according to kinematics equations and detail bonnet tool polishing technique. Abstract: Most of the commenly adotped interpolation algorithems are for the curve machining on CNC machine tools with Cartesian coordinates configuration. For a CNC machine tool with non-Cartesian configuration, new trajectory interpolation algorithem must be developed to machine complex part sueface.

Based on the analysis of the geometric characteristics and the CNC grinding principle of indexable inserts, this paper proposes two interpolation algorithems to grind the nose surface of indexable inserts with constant or variable back angle. The algorithm precision analysis is also made in this paper. Abstract: In order to improve the machining efficiency of the duralumin turbine rotor of maglev molecular pump, this paper proposes a new double-spindle horizontal milling machining center structure.

Through a brief introduction to other types of machine tools, describes the characteristics of this new machine tool and symmetrical machining implementation. This paper proposes a new double-spindle horizontal milling machining centers so that the machining efficiency of duralumin turbine rotors is improve 100% more than that of the traditional machine tool in theory.

Moreover, its machining accuracy get relative improve as the decrease of the dividing accumulative error. At the same time, the cost of workpiece is reduced greatly. Abstract: The 5-aix machining postprocessor of non-orthogonal machine tool is difficult to develop. On the analysis of characteristics of non-orthogonal machining center with dual worktables and 5-axis milling programming, a postprocessing algorithm of 5-axis milling is presented. Based on the algorithm, a postprocessor is developed by Visual C to convert tool path file to G-code file. For tentative validation of the postprocessor, a simulation model of the machine is established by Ver-icut to simulate G-code files created by the program.

Finally a test workpiece is machined, which confirms the validity of the postprocessor. Abstract: Generally, ball end mills are used for free-form surface machining.

When machining curved surfaces with large curvature change using ball end mills, it is necessary to use tools with larger curvature of the cutting edges than the maximum curvature of the surface and minute pick feeds or to change tools for fitting the curvature of one part of the surface. However this causes poor machining efficiency. The curvature of the cutting edge of a flat end mill can be fitted to the curvature of a point on machined surfaces by adjusting the tool posture. Therefore, flat end mills can efficiently cut almost all curvature curved surfaces without tool change. This paper proposes two methods for deciding tool posture and tool path for 5-axis control machining based on minimum cusp height. To decide the tool path, one method defines tool paths along isoparametric curved lines, while the other defines tool paths along curved lines along the minimum curvature direction. The basic system was constructed based on the proposed method, and the effectiveness of the proposed method was verified.

Macro programming is a useful tool for most any CNC machine shop, whether a one man garage or an international conglomerate. Macro programming provides a means of shortening code and doing repetitive tasks easily and quickly. All of your canned cycles in a control are nothing but a macro.

Macro is also extremely useful for families of parts. All computer programming is on a fundamental level, very similar. The syntax of the commands, and purpose of the programming may change, but the fundamentals of how to approach it, how logic works, and program flow are pretty much the same.

The first step to any programming is to define the functionality required of the program. Functionality is defined as the end result(s) and abilities expected of the computer code. In other words, what is it supposed to do. When we write a macro, we have a desired result in mind. Write down the broad-based result you are looking for from the program. A broad-based result would be something like: Bolt circle drilling, rectangular pocketing, block facing, slotting, etc.

For an example, lets use bolt circle drilling. After we have defined the broad-based functionality, we need to narrow down the specifics of what we desire from the program.

We must set limits to the functionality we want to achieve. If no limits are set, then the program becomes too large, cumbersome and time consuming. In our example, one of the main limits we need to set is the maximum number of holes we will be allowed to drill in the macro. For the sake of brevity, lets limit ourselves to 10 holes (We have another question coming up that, in reality, allows unlimited holes using only 10 as a maximum here) So: Max Holes in pattern 10. Next up on the functionality list regarding hole drilling: Do we have a drilling cycle in the machine control or not?

Most of the time, this is going to be a yes, so we will go with that. So: Have drilling cycle in control Yes Next up on the functionality list: Do we want the ability to start the hole pattern at some angle other than directly along one of the major machine axis (X,Y,Z), this is seen often in parts, so yes, we want this functionality. So: Ability to start holes at operator input angle Yes Next: Do we want the macro to call the tool, or will you already have the tool in the spindle when you call the macro? Lets do macro does not call tool. This is really a programmers preference as to which way to go, but since the possibility exists that we could do multiple bolt patterns with the same tool, we wouldn't want to go to tool change position each time between patterns. So: Macro calls tool No Next: Do we want to induce multiples of our max holes? This would allow you to drill more than our stated maximum number of holes.

I think we can implement this in a short manner, so we will do this. So: Macro allows multiples Yes What other functionality should we define?.hrm.for now I can't think of anything, so onward we go with the functionality described above. Ok, Now that we have defined functionality, we need to set some standards with regards to the macro programming. The first thing to consider is the variable table. You have four (4) types of variables: Local Variables: These variables are local to the program. Normally used to transfer values to a cycle call, or as intermediate mathematical value holders.

I hate using local variables because of one major issue with them. They are reset to null (not 0) when the control is reset or the program ends. While perfectly fine for use in transferring variables to canned cycles, etc. They can get you in trouble if you use them for other things. I, just by policy, never use them for anything.

In Fanucese, these are typically #100-#499 (if you have that many available). Local variables are only available to the program in which they are used. Global Variables: These variables, once set, remain set unless you change or reset them via macro or the control keyboard. Unlike local variables, global variables are available to any program in the control.

I use gobal variables because they are retained, can be used in any program, and you can track what's going on if you have an issue. In Fanucese, these are typically #500-#999 System Variables: These variables are available to use in macro programming and allow you to write and retrieve information from the control itself, such as tool in the spindle, tool offset active, write and read offsets, check active codes, etc. Very handy indeed, BUT, these are NOT standardized to a great extent. You will have to consult the macro programming portion of your control manuals to determine what these are. String Variables: String variables are a group of characters interpreted as a single value. Typically defined with a $ symbol.

String variables allow you to manipulate text and phrases etc. Not all controls support string functions. I typically define my variable fields along the following lines: #500-599: Input variables to the macro #600-799: Mathmatical functions of the macro #800-899: Variables needed with regard to tooling, offsets and system variables. #900-999: Logic keep bits, counters, etc. After we have defined our functionality and standardized our variable table usage, we now need to define the inputs to our program that are needed to generate the functionality results we desire. My method is to put the inputs in a separate subprogram from the actual working program. This helps to prevent editing errors from curiosity and just oops in the main macro.

The inputs we need to do our drilling are the following: #500 = Number of holes to be drilled #501 = Bolt circle diameter #502 = Angle of first hole along the X axis at machine coordinate 0° angle. Typically this is the X+ direction. #503 = X axis absolute position for bolt circle center #504 = Y axis absolute position for bolt circle center #505 = Hole Depth #507 = Pecking Depth #507 = R plane clearance #508 = Feedrate for drilling #509 = Clearance height (above part Z0) for rapid movements between holes #510 = Spindle speed for drilling #511 = W function of the G82 drill cycle #512 = E function of the G82 drill cycle #513 = V function of the G82 drill cycle #514 = L function of the G82 drill cycle That's all I can think of right now that we would need to achieve our stated functionality. If anyone sees something missing, let me know, as I'm writing this and thinking it through as I go. Btw, I'm writing this based on the Brother B00 implementation of fanucese. More to come later.

Nice Job Tony! Couple o' things. I worked with a machine tool builder once, that had a bolt circle drilling canned cycle. Either a degree spacing, or a # of holes equally spaced could be programmed.

Also, there was a 'word' somewhere to skip one or more of specific holes in the array. I like to use pass-through variables.

The ones between 1 and 26, inclusive. #500+ can be set from within a program if you don't want to have them be as volatile as you have described.Yes, I've worked with a few controls that had a bolt circle cycle. Handy they are. I'm just using this as an example of how to lay out a program, and some of the basic functionality available with macro programming. Good call 3t3d it is floating point math. I spent about 4 days pounding my head against the wall.

Trying to figure out why when I had IF#23GE#17 GOTO1 and I would look at the variables and the were both be.400 but would not jump to 1. I had to end up using the rounding function to fix it. IFROUND#23.0GEROUND#17.0GOTO1 Tonytn36 Nice work. I just wanted to throw my 2 cents in.

I know that it is the programmer’s decision if the tool call is in the macro. I use this in the macro to keep less data out of the main program with the macro call.

I don’t believe that you should limit yourself to 10 holes for the fact that what happens when you have to do 11 holes? Now the macro has to be changed. I like to look at it as the fact the only thing that can cause the macro to not machine what you want is the few variables that you set in the macro call.

Cnc Macro Programming For Beginners

There should also be specified a bolt circle diameter. I also like to use the Local variable assignments #1-#33 because if a macro call is written and a variable is forgotten then the old variable from the previous program. I know code can be written to check this but that gets into longer macros and more calculations.

My macro calls cosist of 6-8 variables on average. Nice catch on the EQ 3t3d. I should mention that most controllers with macro ability also support RND, FIX and INT functions. On the hole limit of 10.

I chose 10 because from the values 0 - 10, you can achieve all other values needed for number of holes and it can limit the number of calculations you need to do in the macro, by adding just a few. As mentioned, and of note many things when macro programming are 'programmer preference', including whether to use local variables or not.

I just prefer to not use them and that decision is based on the fact that one man was killed because of ill-advised local variable use (3t3d and SwissPro should remember this incident from a.m.c). The biggest key is to be consistent with how you program. You should always have variable range checks in your macro. This is akin to shutting the door on the mill before you plow into a piece of aluminum at 10K and 200 IPM.

It's a safety issue, both for the machine and the operator. Yup, it takes a few minutes to write, and eats up a little memory, but if it saves your machine just once.it's paid for all of that time and effort.

Tony I agree with you 100%. Most of my programs that actually run and loop the part are 10 lines of code but I have 30 lines of calculations that check and alarm in case someone fat fingered a number ect. I was more referring to it is hard to catch a clearance plane for example as you were describing for #509. If you use for example #1 for your clearance at the beginning of the macro you can have IF#1EQ#0GOTO1000(alarm).

Which means if you forgot to set #1 all together it will be equal to null and the calculation will catch that it was never set. However if you run 1 macro setting #509=3 then run another macro when you need a clearance of #509=5 and you forget to include #509 in your program all together it is going to use 3. It’s just a bit harder to catch that in a calculation without making the macro part specific.

Sinumerik Cnc Macro Programming Manual Pdf

As you said it is programmer preference. However I do like to have my clearance planes in the #500 that way there is always something for clearance as long as you’re using #500 in all of your macros.

The way I like to put in safe calculations is take each variable that is being set and 1 at a time run it through every scenario that an operator can change it to and what the outcome would be. Then combine 1 and 2 for outcomes ect. There is no limit to macros except imagination. Great work on breaking down the systematic process for developing a macro. I look forward to seeing your code. Just when you think you know all the tricks someone shows you something you didn’t think was possible. There are quite a few mathematical functions available to us for macro programming.

Some controls offer more extensive operation sets, but I'll stick with the Fanucese standard set for now. NOTE 1: All Fanucese and fanucese compatible variables begin with a pound ( #) sign ( #500). Siemens variables are preceded by an R ( R500). I am not sure what other controls use.

NOTE 2: In a macro logical or mathematical statement, the variable to be written is to the left of the operator sign, while the function (equation) is written to the right of the operator sign. Ex: N30 #500=500+#502 (The results of the equation 500+#502 is written to #500) NOTE 3: For NESTED equations, brackets must be used to delineate the order of operations, if they must differ from the standard order of operations supported by the control. The standard operational order of equations for Fanucese is: First: Functions (Trig Functions, etc) Second: Multiplication, Division, AND Third: Addition, Subtraction, OR,XOR Check your controller manuals for this, as it.does. differ from control to control.

Mathematical Functions: Definition (=) Addition (+) Subtraction (-) Multiplication (.) Division (/) Sine (SIN) Arcsine (ASINE) Cosine (COS) Arccosine (ACOS) Tangent (TAN) Arctangent (ATAN) Square Root (SQRT) Absolute Value (ABS) Rounding Off (ROUND) Rounding Down (FIX) Rounding Up (FUP) Natural Logarithm (LN) Expotential (EXP) Logical addition (AND) Logical or (OR) Logical xor (XOR) Conversion BCD to BIN (BIN) Conversion BIN to BCD (BCD). We have four distinct possibilities that could occur with our bolt circle example. There is an even number of holes, one of which starts on a Major axis.

There is an odd number of holes, one of which starts on a Major axis #3. There is an even number of holes that do not start on a Major axis. There is an odd number of holes that do not start on a Major axis. Now, we could write one macro that would ignore the differences of the four possibilities listed above and programmers preference abodes here. However, in the spirit of this thread, and to show some programming possibilities, we will handle some of these differently.

The differences in the above statements are even vs odd and hole aligned or hole not aligned. Lets look at the even/odd thing first.

How are we going to determine if the number of holes the operator has given us in #500 is even or odd, given the limited mathematical functions available to us in the control? The rule to determine if a number is even or odd is: Is the number divisible by 2 with no remainder. If we take #600 = #500/2 #600 will now be the result. Now if we take #600 and do a little work with it, we can determine if the value is even or not. #601 = FIX(#600) #602 = FUP(#600) What we have done here, is both round UP and round DOWN to the integer. With the FIX command, if the value of #600 was 3.33 the FIX command will round the value to 3.0. With the FUP command, the value will be rounded to 4.0 If you use the ROUND command, it will be rounded to the first decimal, based on normal rounding rules.

Now we can compare our original value, to the rounded values. If the number was evenly divisible, all 3 values should be identical. If the value was not evenly divisible by 2, then the FIX and FUP will return different values and our logic statements will not be true.

IF #600 NE #601 GOTO 400 (Non even number) IF #600 NE #602 GOTO 400 (Non even number) If they are equal, we keep going.in the next post. QUOTE: 'Bluechip, are you saying that the converter changes the Fanuc macro into a common variable program for the Okuma?

CNC XChange will auto-convert all areas of the Fanuc Macro B language including Common Variables, System Variables, Arithematic Operations, Control Commands ( While / Do loops, If, etc., Conditional Expressions ( EQ, LT, etc. Into the compatible Okuma User Task commands / variables. CNC XChange also has an unlimited user defined area where users can set-up their own 'what-to-convert-into-what' in case their control does some specific functions not covered in the hard-coding. Our standard version of CNC XChange will also convert standard Fanuc G code to Okuma OSP code.

Info and video presentations.

Recent Articles

- ✔ 1965 Ford Ranchero Repair Manual

- ✔ Installation Manual Fairchild A100

- ✔ Siemens Mri Service Manual

- ✔ Hatchet Common Core Study Guide

- ✔ Mother Board Chiplevel Repair Guide

- ✔ Production Operation Management Manual Solution

- ✔ Abbott Architect I1000sr Manual

- ✔ This Resistance Training Specialist Manual

- ✔ Mcculloch Eager Beaver 60012312 Manual

- ✔ Childhood Study Guide Answers Key

- ✔ Canon Ir3320i Service Manual

- ✔ 76 Ford F150 Repair Manual

- ✔ Usace Quality Assurance Techniques Manual

- ✔ Suzuki Gsxr 600 Service Manual

- ✔ Do It Yourself Repair Manual 11088752791

- ✔ Repair Manual 2016dodge Journey

- ✔ Ajcc Cancer Staging Manual 5th Edition Colon

- ✔ Ford Manual 62 Falcon

- ✔ 2011 King Quad 500 Owners Manual